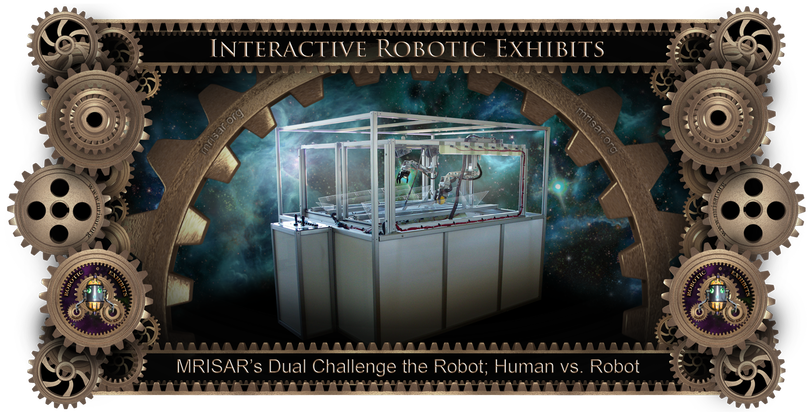

MRISAR's Exhibit Fabrication Images for the

Dual Challenge the Robot Exhibit; Human vs. Robot!

Dual Challenge the Robot Exhibit; Human vs. Robot!

|

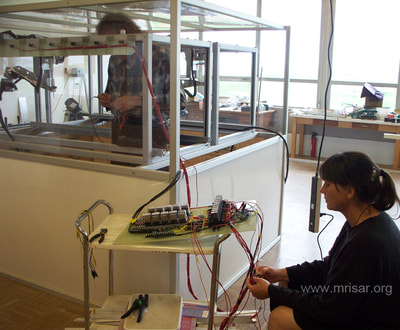

Below is a video and an image gallery of the MRISAR Team during the fabrication and testing process! After being built, it is sometimes broken down for ease of shipping or when sold as a kit. We make reassembly an easy process through the use of custom connectors and frames. We have been making robotic exhibits since 1991! |

|

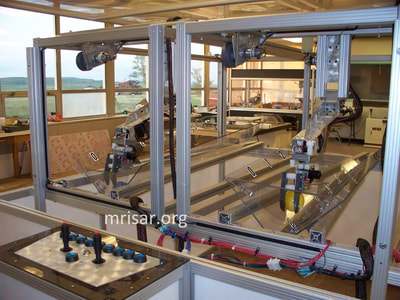

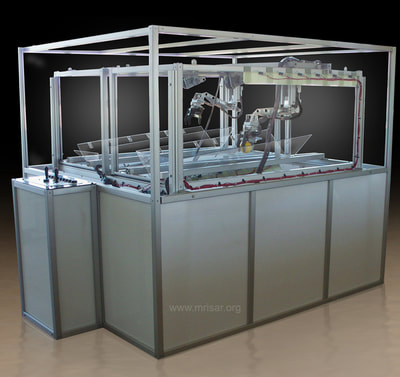

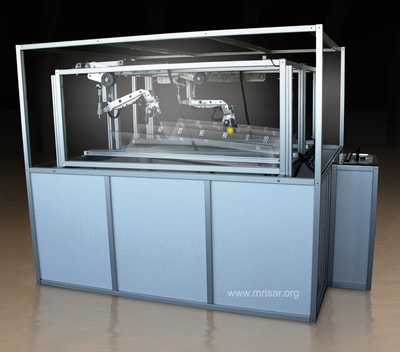

A Rail Robotics exhibit that features three activities. 1- Operated by a museum visitor; 2 and 3- Operated by an instructor for educational demonstrations. General Description; a dual 3-finger robotic arm exhibit. One robot arm is automated and the other is controlled by a user. The challenge is between the manual robot arm that is being controlled by a human and the automatic arm being controlled by the robot’s electro-mechanical brain. The automatic arm picks up a ball and takes it to a number of target locations one by one, while letting it roll back to the starting point between targets. The challenge to the human user is to perform the exact sequence of movements as the automatic arm, without error, and at a faster rate.

*** Visitor Instructions To Challenge the Robot. Read the instructions before pressing start: Do not press the unmarked blue buttons as they are only for special functions that instructors can use and will not respond without a key. 1- Press the start button. 2- Using the manual controls for the left robot arm, try to duplicate the actions of the robot arm on the right, as exactly and as fast as you can without errors. The automated robot arm on the right takes the ball to each target location and then lets it roll back to the beginning position. This process will continue until it stops on the last target and shuts itself off. To complete the challenge, you need to finish before it does. Move the joystick on the left to control the left arm’s forward and backward movements along the rail. Move the joystick on the right to control the elbow and wrist. The red button on top of the left joystick opens the fingers. The red button on top of the right joystick closes the fingers. To maintain a constant pressure grip the close button must be kept pressed while moving a ball. Regarding the Reset Button: If the robot had been interrupted during its automatic activity it might be necessary to push the reset button. Reset can also be used if you feel you want to clear the current game prior to completion. Observations of the Challenge: How far did you get by the time the robot arm finished the task? Did your method differ from the robots and if so did you drop the ball or impact the activity area? Since the arms are both the same and designed to go at the same speed why did the robot still win? Because it does not waste time in extra movements and it is not subject to indecision. What if this was a dangerous life and death duty? Humans have their creative intelligence, but robots are ideal for repeated actions. Consider this with regard to the speed of this challenge. Robots can be designed to move at incredible speeds. The challenge of this exhibit would have been won by the automated robotic arm seconds after it started if we had not given an advantage to the human user by setting the robot arm speed at a rate comparable to a human’s reflex time. ***Instructors Directions To Operate. Read the Instructors instructions before pressing start; Read the visitor instructions if you have not already done so. This set of instructions explains two activities that instructors can do for further educational merit. Activity One: After having a student do the "Visitors Challenge the Robot" activity, the exhibit is started again only this time quickly press a couple of the buttons to the right of the reset button. The first unmarked button to the right corresponds to the first target. The rest to the right of it correspond to the next targets. By momentarily pressing a couple of the target buttons in order before the arm is able to pick up the ball, the instructor can fool the arm’s automatic controls into thinking that the target was already done. This is because its short-term memory logs the switch signal. Now it will skip that spot. Observations: This illustrates one principle of robotics. A robot is only as accurate as it’s sensory inputs. In many automations failure to get a signal from a limit switch or sensor will result in a complete halt. How is this the same and how does this differ from real life? Humans can adapt more easily to change. Robots can be made to do this as well, but for the most part they are still dependent on preset norms. Activity Two: Using the key, set the lock in position. This cuts the signal through the robots lower brain function and switches it over to the unmarked push switches on the left. The buttons will now access the basic movement sets for the arm, but not the higher brain functions. Now try being the higher brain. With practice it will be possible to run the arm through its motions like it does normally by pressing the buttons in the correct order and time duration. Even though this will work it will prove inefficient because sensory feedback cannot cue the arms action. Since the Human Instructor can see and logically interpret the results, it will still perform fairly well. Attention: Move the arm back on the track by using the four push button switches on the left of the reset button before turning the key to its original position. If you do not, the arm will not understand it’s position or call for the right movement sets until the key is turned again and the arm is moved to the back. This arm was made to human proportions. Less bulky plastic versions of arms like this can be used as artificial limbs. While tougher arms can be mounted on mobile carts to help in dangerous situations, like fire fighting and bomb retrieval, as well as on Probes to other planets. Presently robot arms are mainly used in factories, but this is changing rapidly with consumer robotics markets being developed. Each robot arm has five ranges of motions, pressure sensitive and end of travel limits and is made of light weight 6061 Aluminum. Each robot arm is totally open framed for educational viewing which relates to STEM and based closely on the proportions of an actual human arm. It is especially designed with safety features and force limits. The arm is also usable for any age range of visitor. The fingers come in either black or white UHMW. Each side of the upper frame of the exhibit is a window made of clear unbreakable poly-carbonate to make it visible from all sides. The exhibit is configured as a demonstration arm to illustrate remote handling applications for robotics. Remote handling robots are used by industry, aerospace and commercial establishments to extend human capabilities in hazardous situations. This complete exhibit includes a quality built electronic-electromechanical robot arm, fully enclosed exhibit case for the arm, support electronics, visual support materials, maintenance information and schedule, activities and control panel. Approximate size of case is 72” high x 70” wide x 96” long.

Terms: 7-year warranty against defects in our workmanship; Free Life-time phone/internet technical support; Life-time parts supply sourcing for our exhibits at reasonable prices. Contact us for price information. Our Workmanship Quality! Our Terms and Warranty! Our Mission Statement! |